Quality Control for Xray Instruments

NTRODUCTION

The World Health Organization (WHO) defines a quality assurance (QA) programme in diagnostic radiology as an organized effort by the staff operating a facility to ensure that the diagnostic images produced are of sufficiently high quality so that they consistently provide adequate diagnostic information at the lowest possible cost and with the least possible exposure of the patient. The nature and extent of this programme will vary with the size and type of the facility, the type of examinations conducted, and other factors. The determination of what constitutes high quality in any QA programme will be made by the diagnostic radiology facility producing the images. The QA programme must cover the entire X-ray system from machine, to processor, to view box.

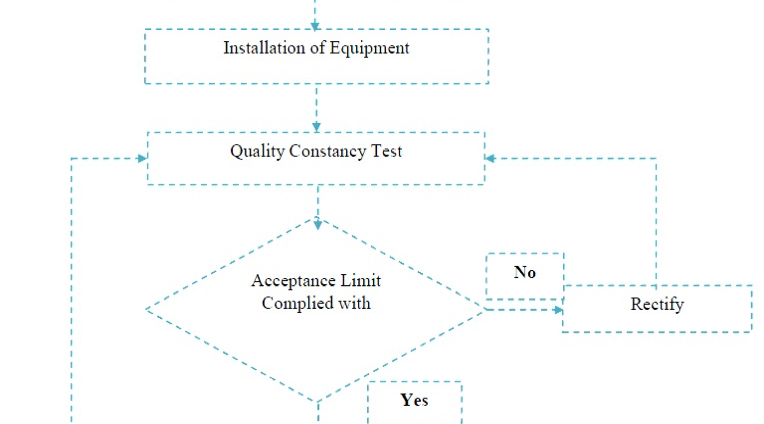

Quality assurance actions include both quality control (QC) techniques and quality administration procedures. QC is normally part of the QA programme and quality control techniques and those techniques used in the monitoring (or testing) and maintenance of the technical elements or components of an X-ray system.

The quality control techniques thus are concerned directly with the equipment that can affect the quality of the image i.e. the part of the QA programme that deals with instrumentation and equipment. An X-ray system refers to an assemblage of components for the controlled production of diagnostic images with X-rays. It includes minimally an X-ray high voltage generator, an X-ray control device, a tube-housing assembly, a beam-limiting device and the necessary supporting structures. Other components that function with the system, such as image receptors, image processors, automatic exposure control devices, view boxes and darkrooms, are also parts of the system. The main goal of a QC programme is to ensure the accuracy of the diagnosis or the intervention (optimizing the outcome) while minimizing the radiation dose

PRINCIPLE OF A QUALITY CONTROL PROGRAM